YOUR VALUE-ADD OEM LIQUID HANDLING COMPONENTS PARTNER

Our customers rely on our durable and long-lasting products to perform accurately and reliably.

Whether servicing the Analytical, Diagnostic, or Life Science fields, it is important your equipment is meticulously designed with your needs in mind.

MK Fluidic Systems collaborates with OEM companies to engineer and manufacture custom fluid handling components, and even offers interchangeable designs. By selecting quality components, you ensure that your equipment performs safely, accurately, and reliably.

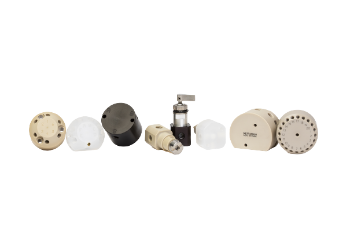

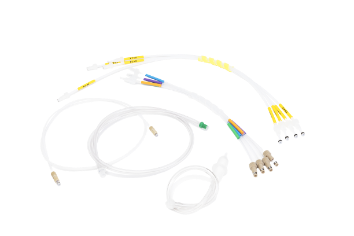

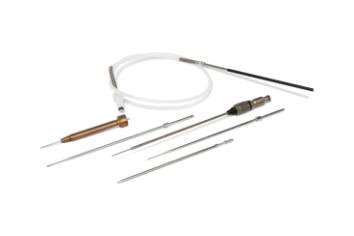

FLUID SYSTEM PRODUCTS

REVIEW AND REFINE REQUIREMENTS

Our engineers will work with your team to develop a design, timeline, performance specifications, and target costs.

PROTOTYPE AND TEST

MK Fluidics has the capability to fabricate fully functional prototypes entirely in-house. Our engineering and quality teams are very experienced and can provide assistance in verification and validation of product requirements.

PRODUCTION

After all of your requirements have been met, our team is ready to support your ongoing production needs. Our prototypes are made using production machinery and methods, significantly reducing risk when moving to full production.