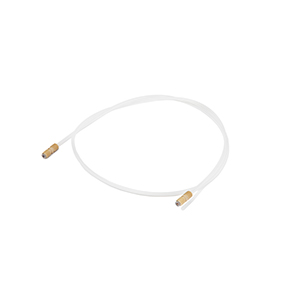

CUSTOM OEM TUBING & FITTING ASSEMBLIES

MK Fluidic Systems offers standard and custom-designed tubing and fitting assemblies for the OEM marketplace for a variety of applications and industries.

INNOVATING NEW PROCESSES FOR QUALITY TUBING & FITTING ASSEMBLIES

MK Fluidic Systems creates custom tubing and fitting assemblies to meet almost any design requirement. Our highly controlled manufacturing process ensures exceptional quality and project success—and we understand that attention to detail is critical to create an exceptional product.

CUSTOM TUBING & FITTINGS IN A VARIETY OF MATERIALS

At MK Fluidic Systems, we work with a variety of inert materials such as FEP, PTFE, PEEK, PFA, Stainless Steel, and KEL-F. A variety of flanged and flangeless fittings are available that can be purchased separately or assembled into tubing assemblies. Custom designs are available for when an off-the-shelf solution is unavailable.

OUR TUBING & FITTING ASSEMBLY CAPABILITIES

TUBING KITS

We manufacture tubing kits with customer specified lengths and connectors including identification tags and probes as required. In addition to providing easy to install assemblies for the OEM's manufacturing process, tubing kits provide the OEM with a convenient configuration for replacement parts in service. If a specific connector is not available in the market, we can design and fabricate what is required in our machine. MKFS can also create custom thermoformed shapes in tubing assemblies, allowing creative flow path solutions.

TUBING FITTINGS

Our fittings are made from PEEK, Acetal, PCTFE, polypropylene, and stainless steel. These fittings have the ability to withstand harsh reagents and operating conditions. Both flanged and flangeless fitting configurations are available to meet your system requirements.YOUR PARTNER FOR CUSTOM OEM TUBING & FITTING ASSEMBLIES

REVIEW AND REFINE REQUIREMENTS

Our engineers will work with your team to develop a design, timeline, performance specifications, and target costs.

PROTOTYPE AND TEST

MK Fluidics has the capability to fabricate fully functional prototypes entirely in-house. Our engineering and quality teams are very experienced and can provide assistance in verification and validation of product requirements.

PRODUCTION

After all of your requirements have been met, our team is ready to support your ongoing production needs. Our prototypes are made using production machinery and methods, significantly reducing risk when moving to full production.