FLUID COMPONENT MANUFACTURING CAPABILITIES

MK Fluidic Systems operates out of a 55,000 square foot manufacturing facility in the Summerlin community of Las Vegas.

Manufacturing Capabilities

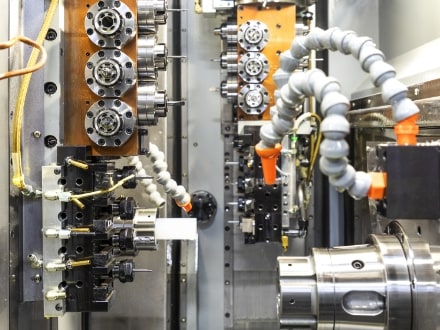

MKFS operates out of a 55,000 square foot manufacturing facility in the Summerlin community of Las Vegas. Built with the highest standards in mind, our facility maintains the latest machinery and equipment used for high volume precision component fabrication.

All customers are welcome to tour our facility.

MANUFACTURING PROCESSES

- CNC Machining

- Centerless Grinding

- Burnishing

- Passivation

- Electropolish

- Mechanical Polishing

- Anodizing

- Needle Tipping

- Flanging & Flaring

- Swaging

- Electrochemical Cut-Off

- EDM Drilling

- Laser Machining

- Laser Welding

- Assembly

- Testing

Machine Shop & Assembly

Design and fabrication of in-line assembly fixtures are completely built in-house to assure each step of the manufacturing process is repeatable and within specifications. These fixtures remove any guess work out of the process of assembly and reduces the chances of repetitive motion injury.

In-line testing allows us to identify any deficiency before moving to the next step in assembly or process. This is cost effective and greatly reduces downstream issues on the manufacturing and production line.

Testing Center

We have an In-house testing center for emulating a customer’s test procedure. We can perform real time and accelerated testing using various types of syringe pumps and system fluids. Our environmental test chamber can be used for special temperature requirements with each testing station conforming to a procedure agreed to with the customer.